System Identification (Process Modelling) Tool

PID loops are often tuned by trial and error which yields sub optimal tuning. In addition it can upset the process due to poor trial values. The recommended procedure for tuning a PID loop with minimal disturbance to the process is as follows:

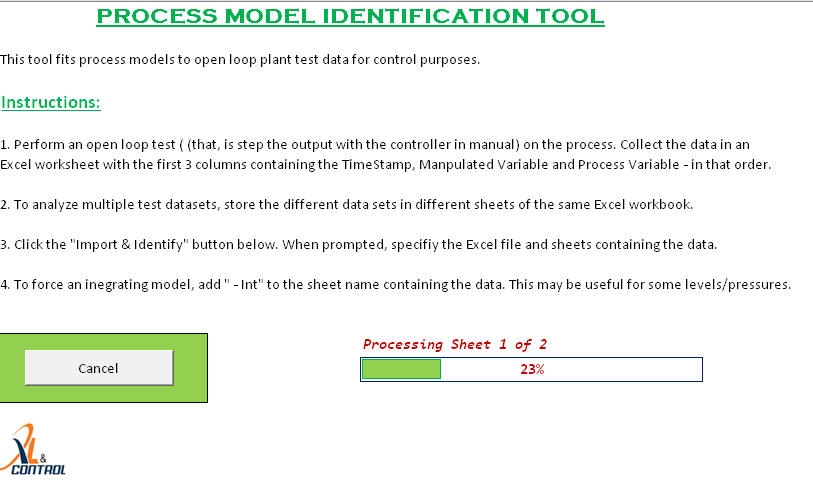

1. Perform an open loop step test and collect test data;

2. Identify process parameters;

3. Simulate the PID tuning offline; and

4. Implement on the controller and fine tune if necessary.

The System Idenfitication Tool is a powerful but very easy to use tool for obtaining process parameters from open plant test data (step # 2 in the procedure above). The tool identifies first order or integrating process models, which are the most common process models encourntered in the chemical process industry.

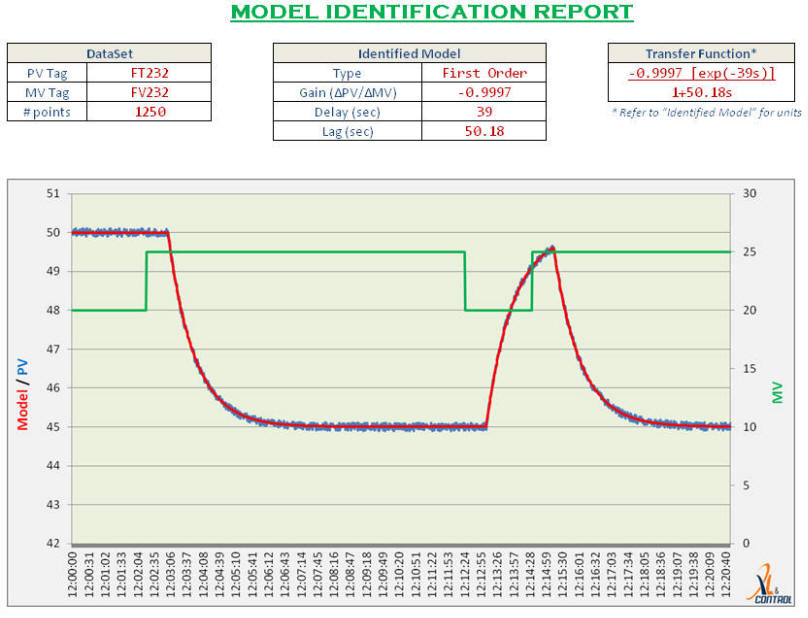

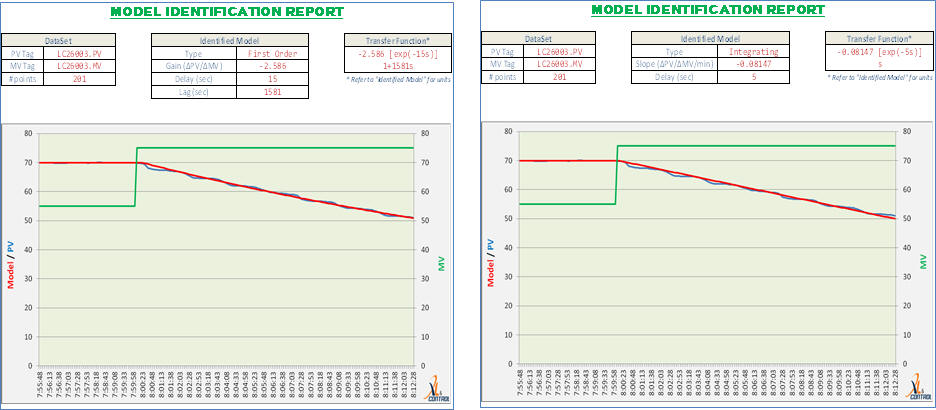

This tool produces an identification report for each data set. Screenshot of a sample report is shown below. (More screenshots here).

Features

- Identifies First Order and Integrating processes, the most

commonly encountered processes in the chemical process industry.

This tool is useful for both regulatory control and APC (Advanced Process

Control) engineers.

- The tool supports various data from different tests - single

step, single pulse, double pulse or Pseudo Random Binary Sequence

(PRBS). See screenshots.

- Parameters from this tool can be used in the PID Loop Simulator for

loop tuning.

- Familiar Excel environment - no installation required

- Intuitive and easy to use, no steep learning curve

- Uses an efficient optimisation algorithm customised for

identification purposes

Test Data Requirements and Sample Data File

The data requirements for this tool are simple and are designed keeping in mind the typical work flow followed by a control engineer while doing plant tests for tuning.

- The data must be provided in an Excel file. Data for a test must

be in a sheet with 3 columns, the first containing the

time stamp, the second containing the controller output values and

the third containing the process values. The first row of the data file must be the headers indicating

the signal names for the controller ouput and the process values.

There should be no gaps (blanks) in the data and the 3 columns must

contain equal number of entries. The screen shot below shows a sample

data set.

The Excel file can contain data from multiple tests. If there are multiple sheets in the Excel file, the user will be prompted to choose the sheets containing the data to be used.

Each selected sheet is processed by the application and a report generated for each data set.

- The data must be collected from a test done with the controller

in manual mode only.

- By default, the identification report provides the results of

the best fit. This works in most cases, but occassionally, there may

be a need to fit an integrating process when it is known before hand

that the process is integrating (examples are levels and some

pressures). In such cases, integrating model can be forced by adding

" - Int" at the end of the sheet name containing the data.

For example, the data sheet with the name "LC123" will show the best fit results, but "LC123 - Int" wil produce an integrating model only. An example is shown in the screenshots below. The picture on the left shows the mathematical best fit, but from process knowledge, we know that this is an integrating process, and the identification can be forced to report the integrating process model.

- Good identification requires good test data. For good results,

start with the PV as steady as

possible and ensure that the data has a good signal to noise ratio.

For good signal to noise ratio, the controller output movement

should be large enough to cause the process value to move beyond the

noise level.

In most cases, a single pulse or double headed pulse test usually yields good results. See screenshots for examples of test types.

Important: No responsibility is assumed for incorrect use of this application. Having an understanding of the process is a pre-requisite for tuning any loop. Should training and/or tuning services be required, please email sales@xlncontrol.com with the requirements to obtain a quote.

Testimonials

We are grateful to Mr. Martin Kenkel from Germany for his appreciation. Mr. Kenkel has provided great feedback on both this tool and the PID Loop Simulator which have all been incoporporated into the products.

"For people who have access to process values, I recommended the Process Modeling (System Idenification) Tool, thus eliminating logging while jump attempt and simplifies the evaluation. I compared and found the results are very similar to the manually determined values. The parameters determined can be transferred to the PID Loop Simulator. For documentation purposes, the Excel sheets can simply print out. Finished! The time you saved can be used for other things. For questions or problems you get quickly and competently help.

My conclusion: I highly recommend this both programs! It has made my job easier. The PID Loop Simulator should be mandatory for schools / training centers!!"

If you like this tool, a short testimonial would be highly appreciated.

Purchase

Payments can be made using credit/debit card or PayPal. Payments are processed by Gumroad.

License Type: Single User

Licensed to a single user, user can make multiple copies for own use.

Price: US $ 899

Payments can be made using credit/debit card or PayPal. Payments are

processed by e-junkie/Paypal. A download link will be available on

payment. The download link will also be emaied to the purchaser.

Site wide / Enterprise wide license/Training license/System Integrator license

Please email sales@xlncontrol.com to request for a quote, specifying the expected use for the product(s) and the expected number of sites or users.

Refund Policy

We are confident that you will find this app very useful. If, however, you are not satisfied with it for any reason, please email sales@xlncontrol.com within 30 days of the purchase for a full refund of the purchase price. A short note describing the reason for the disappointment is optional, but would be appreciated.